Fiber optic cable helps in transmitting huge amounts of data over long distance in a flash. It relies on the clear pathways to transmit the light of data. Invisible dust particles settled on the core of fiber can cause the signal loss resulting higher error rate and lowered network performance. That’s the reason why regular cleaning and preventative maintenance of fiber cable system is so important.

WHERE AND WHEN TO PERFORM THE MAINTENANCE

ICTO performs the maintenance of fiber optical cables every year. Maintenance work starts at the first quarter and completes at the third quarter of year. We access all ELV rooms in each building and residential colleges to perform the cleaning, inspection and repair. In addition, we also perform the checking and inspection of the outdoor fiber that is under manholes. The total number of ELV rooms that we visit for maintenance are 416 and the total number of manholes in UM campus are 36. The total number of fiber optical cable we inspect every year is about 5484 cores.

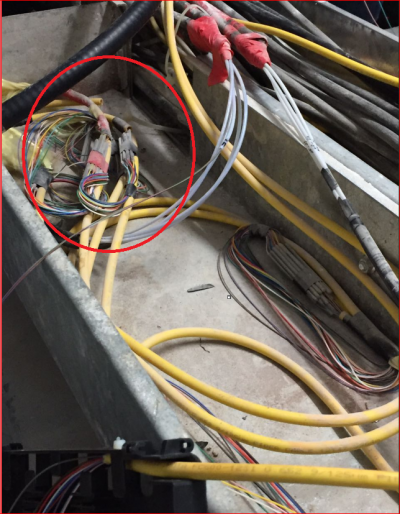

Figure – Manholes in UM campus and the outdoor fiber optic cables

HOW TO PERFORM THE MAINTENANCE

The golden rule of fiber maintenance is inspection, cleaning and inspection again. Repair and replacement are performed if the cables still do not meet the necessary standards after cleaning. Fiber optic cable should be inspected by certified machines but not just visually by eye. Tiny scratches or dust spots may affect performance, so the inspection process should not be performed by the naked eye alone. Wipes and solvent are the two necessary tools for cleaning, the fiber optic cables that fail initial inspection are wiped with the cleaner or wet wipe then dried properly before it is inspected for the second time.

The fiber optic cables are repaired and spliced if it still does not meet the standard. Fusion splicer is the tool used. Splicer produces some type of heat or electric arc to “fused” or “welded” fiber ends together.

Figure – Cleaning tools, fiber testing machine and fiber fusion splicer